联系我们,获得免费资源!

联系我们,获得免费资源!

Thomson 精密梯形丝杠

Thomson 精密梯形丝杠

全球最全面的执行器选择方案

Thomson 直线运动系统

请选择您的登录帐户

选择解决方案

更快、更简单、一点即达地找到适合您的解决方案

根据应用需求,确定系统规格和型号

通过零件编号或产品线名称选择

如有需要,可随时联系Thomson

需要特殊加工?联系Thomson

Select Product Type

滚珠丝杠/螺母组件

+/- 0.004 in per ft, 23 microns per 300 mm

滚珠螺母

法兰滚珠螺母(左旋)和螺纹滚珠螺母(右旋)。

滚珠丝杠

标准滚珠丝杠工作更加平顺。

Ground Screw/Nut Assembly

+/- 0.0005 in per ft

轴承支撑

适合Thomson滚珠丝杠组件的安装解决方案。

法兰螺母

含一体式法兰。

螺纹螺母

适用于大多英制螺母的螺纹法兰选件

圆柱形螺母

Compact, suitable for custom mounting.

Adjustable Preload

Adjustable Preload Ball Nut.

Fixed Support

驱动端双轴承

浮动(简单)支撑

支撑端单轴承

MK - 电机适配器

法兰底部安装、机加工丝杠、固定型

BK - 固定轴承支撑

底部安装、机加工丝杠、固定型

FK - 固定轴承支撑

法兰安装、机加工丝杠、固定型

Universal Fixed Bearing Support

Flange or base mounted, screw is machined, classified fixed

BF - 浮动轴承支撑

底部安装、机加工丝杠、简易型

带法兰的浮动(简易)轴承支撑

法兰安装、机加工丝杠、简单型

通用浮动(简易)轴承支撑

Flange or base mounted, screw is machined, classified simple

选择适合您应用的滚珠丝杠组件

滚珠丝杠组件是一种将旋转运动转化为直线运动的机械装置,其内部摩擦阻力低,因而可承受高推进负载。加之公差等级高,非常适合高精度的应用。为特定应用选择滚珠丝杆组件时需经反复试配,才能找到外壳紧凑、经济划算的解决方案。以下是选择滚珠丝杠组件时最常用(部分)设计考虑的列表。

- 压缩或拉伸负载

- 线速度

- 位置精度和可重复性

- R所需使用寿命

- 安装配置

- 规格限制

- 输入功率要求

- 环境条件

在计算滚珠丝杠组件的直径、导程和负载能力前,应至少已知设计负载、线速度和位置精度等输入信息。然后根据使用寿命、规格限制、安装配置和环境条件选择单个滚珠丝杠部件。

如何安装

装配配置

第一步 - 绘制运动曲线

输入运动曲线参数

| 运动曲线输出 | 公制 | 英制 |

|---|---|---|

| 最大速度 | ||

| 加速度 | ||

| 平均速度 | ||

| 移动时间 |

运动曲线

- 梯形:加速度、恒速、减速度

- 三角形:加速度、减速度

- 自定义多个分段:根据需要创建运动曲线分段,并分别进行定义。

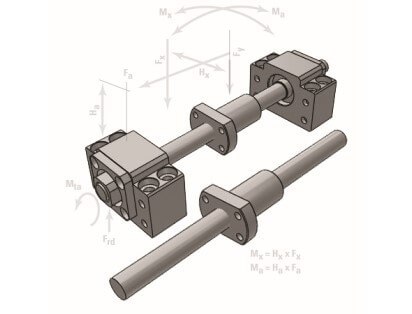

End Fixity Type

末端固定是一种用于支撑滚珠丝杠组件末端的轴承配置。此处展示了3中常见的末端固定配置选项。固定加自由的组合方式支撑较少,而固定加固定的组合方式支撑较多。末端固定可影响丝杠的最大RPM和屈曲负载。

Move Profile Type

运动曲线分为三个等时间段或等距离段(加速度、恒速、减速度)。更多自定义选项,可查看多分段运动曲线选项。”

Threaded Length

末端支撑间距离(丝杠螺纹长度)。

移动距离

螺母行程距离总长。该距离不一定是总行程长度。

第二步 - 输入应用数据

输入负载力

| 轴向力计算 | 公制 | 英制 |

|---|---|---|

| 最大轴向力 | ||

| 同等工作负载 | ||

| 加速度力 | ||

| 加速距离 | ||

| 恒速时的力 | ||

| 恒速时的距离 | ||

| 减速度力 | ||

| 减速距离 | ||

| 摩擦系数 |

行程方向

默认丝杠的方向与地面平行或垂直于地面。对于其他方向以及定制的丝杠,可选择自定义,输入从水平方向测得的角度。

导轨轴承类型

负载由导轨支撑。摩擦系数适用于导向轴承系统。在上图示例中,负载由一根方形导轨(滚珠)系统支撑。

例如,如果使用了滚珠衬套,则摩擦会远远小于使用滑动轴承的情况。摩擦越小,滚珠丝杠移动负载所需的驱动力就越小。

该摩擦力可使用下列公式计算:F = µ N

其中

F是摩擦力

µ是摩擦系数

N是法向力

如果应用的导向轴承类型未知,请在下拉列表中选择Fluoronyliner。由于该轴承的摩擦系数最高,因此将为驱动系统所需的额外力构建“最坏情况”。

负载

压缩负载:一种轴向挤压丝杠的作用力。

拉伸负载:一种从某个方向拉伸丝杠的作用力。

选定拉压负载后,可计算柱状屈曲值。

如果选择“仅拉伸负载”,柱状屈曲值将不会纳入计算。

负载质量

负载质量 = 被移动对象质量。

该质量用于计算加速度力和摩擦力。

Axial Forces

除质量外,螺母受到的轴向外力(如有)。 某些分段的作用力可为零。

根据应用需求,可定义各段的轴向力。

第三步 - 选择应用部件

选择末端个、仅末端加工、或带末端支撑的末端加工

选择末端支撑前,请完成第一步。

| 末端处理输出 | |

|---|---|

| 末端固定: | |

| 螺母方向: | |

| 延长丝杠方向: | |

| 左支撑: | |

| 右支撑: |

该工具允许配置标准Thomson末端支撑的加工。如果需要特殊加工请联系Thomson。

选择螺母型号

根据您此处作出的选择,提示可选螺母型号 。请参阅右侧表格。

Flanged Nut

667可选

包含集成或可选螺纹法兰

Threaded Nut

249可选

不带螺纹法兰的螺母,但可选择配备螺纹法兰。

Cylindrical Nut

222可选

紧凑型,适用于定制安装。

可选螺母表格 (表格将随着您完成第一步和第三步的操作而不断更新。)

测试结果代码基于左侧输入值,有助于确定符合您应用标准的直径和节距。可调整输入值来获得最佳定制结果,如降低所需速度来增加找到理想丝杠直径和节距组合的几率。

Click any cell in the availability grid for more information.

| 标称滚珠丝杠直径(mm) | 节距(mm) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 2 | 3 | 4 | 5 | 10 | 20 | 25 | 32 | 40 | 50 | |

| 10 | ||||||||||

| 12 | ||||||||||

| 16 | ||||||||||

| 20 | ||||||||||

| 25 | ||||||||||

| 32 | ||||||||||

| 40 | ||||||||||

| 50 | ||||||||||

| 63 | ||||||||||

| 80 | ||||||||||

| 标称滚珠丝杠直径(英寸) | 节距(英寸) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.125 | 0.200 | 0.250 | 0.413 | 0.473 | 0.500 | 0.660 | 1.000 | 1.500 | 1.875 | 2.000 | |

| 0.375 | |||||||||||

| 0.500 | |||||||||||

| 0.631 | |||||||||||

| 0.750 | |||||||||||

| 0.875 | |||||||||||

| 1.000 | |||||||||||

| 1.150 | |||||||||||

| 1.171 | |||||||||||

| 1.500 | |||||||||||

| 2.000 | |||||||||||

| 2.250 | |||||||||||

| 2.500 | |||||||||||

| 3.000 | |||||||||||

| 4.000 | |||||||||||

| Chart Key | |

|---|---|

| 通过测试 | 动态负载故障 |

| OAL长度故障 | 屈曲故障(已选定压缩负载) |

| 速度故障 | 不支持末端支撑 |

| 末端支撑负载故障 | 不适用该直径和节距 |

| Thomson end supports available | |

所有颜色(除深灰色)均可选的螺母。

除绿色螺母外,其他所有颜色螺母均有百分之一的可能造成机器故障。

Thomson英制产品线

Thomson英制产品线提供英寸规格的精密轧制滚珠丝杠,直径/行程组合全面。英制滚珠螺母包括非预加载或预加载双螺母两种外部循环系统选择。

产品可得性表列出了符合输入规格和曲线参数的直径/行程组件。如产品不符合要求,请参阅图表图例了解产品可得性及其原因。

Thomson公制产品线

Thomson公制产品线提供P5级精度的精密轧制滚珠丝杠。公制滚珠螺母配备内部循环系统,运行更加安静平滑。

产品可得性表列出了符合输入规格和曲线参数的直径/行程组件。如产品不符合要求,请参阅图表图例了解产品可得性及其原因。

Chart Key

除绿色以外,可能有多种颜色出现在同一单元格中,表明多种产品不可得原因。

Save Your Project

End Support Selection

Selecting End Supports (3 Step Process)

Step 1

What is the difference between these options?

view more

Step 2

Next select between ending the screw at the end supports or continuing the screw through the end supports for either or both ends.

What is the difference between these options?

view more

Step 3

Lastly, CLICK on the two buttons below to select the end supports you wish to have added to your assembly on the right.

Not sure what the differences between the end supports are, or need more information on any particular end support? view more

All relevant part numbers in the proceeding solution table will reflect the same end support choices to allow easy price comparison.

End Support Types

For most applications, the ball screw ends(s) will be supported with a bearing. Configurations that are commonly used to support the ends of a ball screw are:

- A pair of back-to-back (fixed support)

- A deep groove radial bearing (floating or simple support)

Three combinations of bearing supports are typically used. Fixed on one end and free on the other offers the least support where Fixed on both ends offers the most support. Screws with more support are able to support higher loads without buckling and obtain higher critical speeds.

Nut Directions

In a screw that is asymmetrical, or one end is different than another like in a fixed free or fixed floating combination, when installing the nut the factory needs to know how to orient the nut. If the screw is symmetrical, or the same on both sides, feel free to select the default (Right).

End Support Machining

To fit a bearing support to a ball screw, a bearing journal must first be machined into the screw. The maximum diameter of the journal is limited by the screw geometry. Enough of the screw must be machined away to provide a shoulder for the bearing to seat against. The recommended maximum journal diameter is usually near the ball screws root diameter.

Example machined end (top) and machined end with a bearing block installed (Bottom)

To attach a ball screw to a drive system, a drive extension is machined into the screw. When ordering a ball screw assembly with bearing blocks or a ball screw with standard end machining, it is important to specify if this drive extension is wanted on one or both ends. The shaded area in the diagram above represents the drive extension. See the specific end machining details in the product catalog or specifications on the web.

End Support Selection

BK and BF: Base mounting configuration.

FK and FF: Flange mounting configuration.

MK: MK is an FK bearing support with a motor mount bracket.

WK: Flange mounting configuration with higher load capacity bearings.

Standard Ball Screws

作为高精度、高负载应用的理想之选,公制和英制滚珠丝杠符合高规格的生产标准,内部摩擦阻力低,可将旋转运动转化为直线运动。

为何选择Thomson滚珠丝杠?

并非所有精密滚珠丝杠都生而精密。Thomson对设计、质量、材料、生产和应用支持的专注使我们在竞争中脱颖而出,也是我们持续数十年获得成功的秘诀。

如果标准的Thomson滚珠丝杠不能满足您的特定规格需求,我们的工程专家可为您的应用定制解决方案。无论是大量采购,还是简单的部件修改或是复杂的装配,我们都可以根据您的需求定制功能来提高机器的性能。

不知从哪里入手?

Thomson提供丰富的在线资源,无论您的购买决策处于哪个阶段,都可以为您提供帮助:

Thomson滚珠丝杠有哪些用途?

凭借高质量、长使用寿命和可靠的支持服务,Thomson滚珠丝杠占据全球市场已有将近1个世纪。本视频介绍Thomson滚珠丝杠生产过程、选型、定制选项、应用以及在线资源等。观看视频后,您也可以反问自己“Thomson滚珠丝杠对我而言有哪些用途?”

VIDEO: Thomson Smart Actuators: Designing Smart Machines with Smart Tools

视频:充分改善直线运动设计的负载能力、使用寿命和紧凑度

实施任何新应用都需要对产品性能、使用寿命和成本进行仔细分析,尤其是需要处理大负载的应用。了解为何应在未来的直线运动应用中考虑使用高负载滚珠丝杠而不是标准滚珠丝杠。

演讲人: Markus Brändle,产品线专家 - 丝杠、螺旋升降机和LB&G,Thomson Neff Industries,德国

视频:技术技巧:如何将滚珠轴承安装到公制系列滚珠螺母上

如何将轴承重新安装到单循环滚珠螺母上。通常滚珠螺母是单循环滚珠螺母。但该技巧也适用于滚道循环滚珠螺母。

借助Thomson Electrak HD直线执行器的同步选项,Spika Design and Manufacturing公司为客户打造性能、功能性和安全性更出色的作业平台。

Technical Articles

-

Because ball screws are available in both inch and metric dimensions, designers sometimes begin the specification process by selecting a product family based on the unit of measure. This decision may prematurely exclude the ideal product for the application and lead to significant losses in time, labor and expense. This article explains how sizing and selection questions centered on performance – instead of product monikers – can lead to more efficient linear motion designs.

-

Roller screws have been promoted as the only technology of choice for handling large loads when size is a constraint. But in actuality, advances in ball screw technology have now enabled the capability to support high-load applications as well. This is important because a high-load ball screw is typically less than half the cost of a comparable roller screw at equivalent performance points.

-

滚珠丝杠–协作机器人安全高效运动的秘诀

Used in large-scale production applications that involve continuous lifting operations but still require a human touch, collaboration robots (cobots) are gaining popularity. A French cobot maker has developed a solution that uses ball screw and cable actuators instead of gears, setting a new benchmark for cobot efficiency and safety.

了解更多

手册

| Flanged Metric Precision Rolled Ball Screws (16 - 50 mm) | 756 KB | |

| High-Load Ball Screws | 395 KB | |

| High-Load Ball Screws | 370 KB | |

| High-Load Ball Screws | 391 KB | |

| Metric Precision Ball Screws (Made in Germany) | 1053 KB | |

| Metric Precision Ball Screws (Made in Germany) | 1062 KB | |

| 小型公制精密滚珠螺杆 | 625 KB | |

| 小型公制精密滚珠螺杆 | 655 KB | |

| 小型公制精密滚珠螺杆 | 668 KB | |

| Miniature Components and Systems | 6871 KB | |

| Miniature Components and Systems | 6871 KB | |

| Miniature Components and Systems | 6862 KB | |

| Miniature Components and Systems | 6862 KB | |

| Miniature Components and Systems | 1603 KB | |

| SFM Safety Nut | 446 KB | |

| SFM Safety Nut | 442 KB |

产品目录

手册

Technical Articles

| Ball Screws – an answer to safe and efficient motion for Cobots. | 2020-01-01 | |

| 2019-04-26 | ||

| 2016-01-14 | ||

| 2016-01-04 | ||

| Correct Lubrication is Vital to Ball Screw Life | 2015-01-07 | |

| Ball Screws Go Green - the three “R’s”; Reduce, Re-use, and Recycle... | 2009-02-01 | |

| + 滚珠丝杠组件 | |||

| 滚珠丝杠组件-英制 |  |

— | — |

| 滚珠丝杠组件-公制(北美) |  |

— | — |

| 滚珠丝杠组件-公制(欧洲) |  |

— | — |

| + 滚珠螺母 | |||

| 法兰滚珠螺母-英制 |  |

— | — |

| 法兰滚珠螺母-公制 |  |

— | — |

| 螺纹滚珠螺母-英制 |  |

— | — |

| 螺纹滚珠螺母-公制 |  |

— | — |

| 圆柱形滚珠螺母-公制 |  |

— | — |

| + 末端支撑 | |||

| 滚珠丝杠末端支撑-英制 |  |

— | — |

| 滚珠丝杠末端支撑-公制 |  |

— | — |

| + 丝杠 | |||

| 精密磨削滚珠丝杠-英制 |  |

— | — |

| 精密磨削滚珠丝杠-公制 |  |

— | — |

| + 附件 | |||

| 滚珠丝杠法兰 |  |

— | — |

| 滚珠丝杠刮刷器 |  |

— | — |

To provide better service to you on our websites, we and our service providers use cookies to collect your personal data when you browse. For information about our use of cookies and how to decline them or turn them off please read our cookie policy [available here].